This post makes up the first part of making a silkscreen frame. Remember that silkscreen and print screen refer to the same printing technique. Silkscreen is the term applied to the time when the silkscreen mesh was actually silk, between the 18th century and the first half of the 20th century. Print screen is the term applied from the time when the mesh ceased to be made of silk and started to be synthetically manufactured with the discovery of nylon, at the end of the 19th century. But both terms are still used, regardless of its mesh origin, perhaps the silkscreen is more used in manual technique and the print screen in mechanized model like the industrial screen printing. But to differentiate the artistic from the non-artistic there is still the term serigraphy, created by the American National Serigraphy Society, in 1940. You can read more about it in the History of Screen Printing post.

The silkscreen frame, usually made of aluminium or wood, is one of the most important silkscreen printing process pieces, as it holds the stretched mesh, where the matrix corresponding to what you want to print is developed.

Nowadays, the frame is not an expensive piece, costing from around $25.00 (plus shipping) for a model in aluminium and 120T mesh, measuring 50×60 cm, for example, but also depending very much on the brands, manufacturers and countries of origin. Apart from the convenience of coming perfect from the factory, aluminium avoids the maintenance required by wood. However, it is possible to build the frame at home and, in this case, wood becomes more viable, with the advantage of being able to make it in customised sizes, different to the standard sizes supplied by the shops, as well as being able to replace the mesh easily when necessary.

However, making the frame by hand only pays off for those who have access to the right tools to produce perfect frames, otherwise the cost of the material will turn out to be more expensive than buying the frame already made, although the investment can be quickly recovered if there is continuity in the silk-screening experience as more frames are produced.

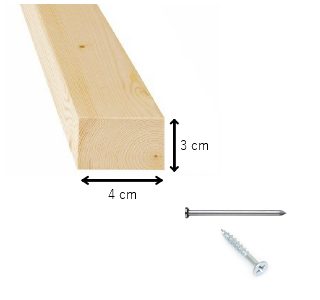

If you buy the profile or the frame already made, it is natural to find reference to hardwoods and Swedish redwood, for example, for a high quality product, but in this context of home production it is feasible to choose untreated pine wood, well dried, in small strips to the desired size, 2 to 3 centimetres thick. Either for fixing the joints or for the posterior fixation of the mesh, the most practical tool is the stapler used by upholsterers, but hammer and nails or even waterproof contact glue may be applied.

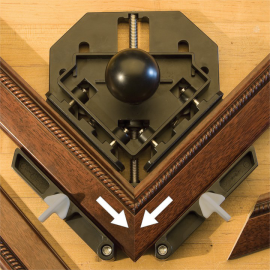

One of the most economical and simple processes for constructing the silkscreen frame is to use a half square box for cutting the slats and 90º clamps for squaring and gluing. The application of the staples or nails should be done at the end, already after the gluing and period of the frame in clamps tension.

To begin with, choose a small frame size, 30×40 or 30×30 or even smaller (in centimetres).

3F 4616MM / 15MM

Other superior clamp options

Any frame joint option is effective as long as it is well elaborated, that is, the final result must present squareness precision without warping, and solidity in the joint, since such aspects substantially interfere in the printing quality, affecting the homogeneity of the stain, definition and register.

Nails

In the case of using nails or screws instead of staples, opt for galvanised material, but the protective effect of galvanisation is ineffective on cedar and treated wood, which is why rough pine is the appropriate choice for making the frame.

Most Common Silkscreen Frame Joints

Find references and more knowledge in Learning Links.

Thanks a lot for sharing 🙏

Thank you!!!

My pleasure 🙏🌹🙏

Thanks for the information. I also read your post about the history of screen printing but was unable to leave a comment.

Of all the printing methods I’ve done (screen printing, etching, lithography, and wood cut) screen printing was always my favorite. I learned screen printing in high school many, many years ago. We used lacquer film and an X-acto knife to cut the stencil then adhere that to the screen with lacquer thinner. Emulsion was too costly, or so my art teacher said, for us to learn that technique, so I have no experienced with that method. I’d like to learn that someday….

Wow! Amazing comment! Thanks!

I wish I had learned screen printing in high school! It would have been fantastic! I learned semi-industrial screen printing at the age of 20 from a perfectionist master screen printer. Then I dedicated myself to other types of printing for the next 25 years, but I developed hand screen printing almost as a hobby because it is really a timeless, effective, fascinating technique. You can’t laser print without having laser equipment, but you can screen print anywhere and without any equipment at all. I even think that the more manual and rudimentary it is, the more fascinating it is. There are those who do screen printing using only sunlight and a piece of old fabric torn from a curtain :).

Thank you very much for stopping by! Loved it!

Hi D. For some reason, the Reader at WordPress.com isn’t letting me follow you?! I’ll continue to try, and, in the meantime, wish you a great day!

Hi, Phil! Thanks for the concern! I don’t know why! It happens to me too, regarding some other blogs. I think they are temporary bugs in WordPress itself, but in online forums they say it’s because of the number of blogs you follow. If you follow too many blogs it happens WordPress will prevent you from following some blogs from time to time because there are a reasonable number of blogs to follow, they say…

Thank you, D. After several attempts, I was finally able to follow you 🙂

Weeeeeeeee! Yeeeee! 👏🏻👏🏻👏🏻👏🏻👏🏻👏🏻👏🏻👏🏻 Many thanks! 🙏🏻🙏🏻🙏🏻🙏🏻🙏🏻

Thanks alot for sharing

Thank you for stopping by! 🙂

Very informative post on screen printing technology! Screen printing is one of my favorites among all printing techniques. Although screen printing has been used since the 18th century, the availability of inkjet printer transparency film makes it the best technology available today. The best thing about inkjet transparency film is that it is waterproof and creates a clean, and clear, high-quality print for any text and graphics. It is versatile and can be used for a variety of applications.

Thank you very much for stopping by! I loved your website, great equipment screen printing supplier. That inkjet printer transparency film seems an excellent product indeed. It is not suitable for halftone printing, but a perfect solution for opaque prints. Thanks!

👌👌

Thank you! ☺️ ☺️ ☺️

🙏🙏

Thank you!!!

☺️☺️

Worth sharing about print screen ????

Of course! It’s a beautiful printing technique ;).

Nice ????